Virginia Tech Seafood researchers work with oyster hatcheries to grow climate resiliency

Virginia’s aquaculture industry brought in more than $177 million for the commonwealth in 2019. Shellfish, including oysters and clams, comprise up to 84 percent of the total economic output from aquaculture.

With the start of November and Virginia Oyster Month, we are finally in the thick of the oyster season. But were we ever out of it? The notion that months with names containing an "r" are best for enjoying oysters still proliferates foodie circles, but thanks to modern shellfish aquaculture, oysters defy seasonality.

If you've ever eaten an oyster — be it steamed, fried, or on the half shell — it was likely grown by a farmer. About 95 percent of oysters consumed worldwide are cultivated, and while aquaculture has helped the industry meet growing consumer demand, climate pressures impacting water quality have complicated oyster and bivalve production.

As erratic water quality and other environmental factors make delivering oysters to the dinner table trickier, researchers at the Virginia Seafood Agricultural Research and Extension Center are working with research and industry partners to adapt recirculating aquaculture systems for oyster culture.

"We are very heavily dependent on quality ambient water coming into the hatchery for good, consistent larvae production," said Mike Congrove, owner of Oyster Seed Holdings oyster hatchery on Gwynn's Island in Mathews County, Virginia. "That's frankly rarely the case. In any season, poor conditions in the [Chesapeake] Bay can hamper production in the hatchery for several weeks or even lead to months of poor production."

“Anything and everything that we're seeing in the coastal waters really impacts all types of coastal aquaculture,” said Michael Schwarz, Virginia Seafood Agricultural Research and Extension Center director. “We're a long way away from understanding all of the water quality and water chemistry issues that are in the bay, but the center is very comfortable with recirculating aquaculture systems.”

In Virginia coastal waters, rising temperatures, more frequent rain events carrying pollutants into the water, and changes in salinity and dissolved oxygen are some factors leading to increased mortality in shellfish hatcheries, particularly by mid-summer going into the fall.

“The changes to water quality and chemistry pose a challenge for the plants and animals that once thrived in coastal ecosystems, and many coastal communities and industries are having a hard time adjusting to some of the changes as well,” said Schwarz, who is also associate director for the Center for Coastal Studies and is working to expand Virginia Tech research capacity on the coast via the Virginia Tech Coastal Collaborator.

Driven by industry need, researchers at the Virginia Seafood Agricultural Research and Extension Center are working alongside industry partners, Virginia Sea Grant, the Virginia Institute of Marine Science (VIMS) in Gloucester, and the VIMS Eastern Shore facility to break the dependence of oyster hatcheries on increasingly unpredictable ambient water quality.

Shucking the status quo

The industry standard uses flow-through, or “batch,” culture by pumping in and using coastal waters to produce hatchery seed. While some mechanical filtration may be used, such as filters to remove larger particles or even some UV sterilization, Schwarz said that's increasingly not been enough to address biological toxins or water chemistry challenges that result from changing coastal environments.

“Hatcheries are experiencing losses or are having to shut down production earlier in the year because the conditions in the environment aren't suitable,” said Jonathan van Senten, assistant professor in the Department of Agricultural and Applied Economics and assistant director of the Virginia Seafood Agricultural Research and Extension Center. “What was needed is a shift in approach.”

Instead of continually pumping in and filtering water from the bay, utilizing recirculating systems could allow hatcheries to pull in water when conditions are optimal and even start filtering and recycling the water months before it’s needed.

"By combining classical and modern microbial ecology with recirculating system designs from finfish culture, we were able to develop a bioreactor treatment system to remove ammonia, left over algae food, potentially harmful bacteria, and other waste products from larval culture water,” said Dick Snyder, director of the VIMS Eastern Shore Lab.

With the goal of increasing control inside hatcheries, researchers from the Virginia Seafood Agricultural Research and Extension Center and the Virginia Institute of Marine Science began to design and test a recirculating aquaculture system for oyster hatcheries with Virginia Sea Grant funding in 2019. The first iteration of the system was designed and tested by Snyder with Chris Bentley at the VIMS Eastern Shore Lab.

Congrove caught wind of the group's encouraging initial findings and teamed up to test the system in his commercial operation with funding support through the Virginia Fishery Resource Grant Program.

“We hooked up with the Virginia Institute of Marine Science and Virginia Tech after their initial bioreactor trials in 2019 to begin some really small-scale trials here in the hatchery with a recirculating system,” Congrove said. “Hearing that they did not have funding to run further trials the next season, we said let’s bring it over to our hatchery and had we pretty good success with those small-scale trials and decided to take it to the next level.”

The research team has since secured a Saltonstall-Kennedy grant through the National Oceanic and Atmospheric Administration of roughly $170,000 for a study that began this year to further bring the collaboration together and improve the filtration system.

While Schwarz and his team test samples to monitor the health and efficacy of the filtration system, Congrove can monitor and compare larvae produced from the main Oyster Seed Holdings hatchery with the recirculating system in an industry setting. The objective long-term is to refine the system so it can be scaled-up for commercial hatcheries to integrate into their own systems.

“VIMS and Virginia Tech bring the academic know-how and the support, and we bring a lot of practical experience in commercial-scale larvae culture,” Congrove said. “We’re optimistic about this round of research because the work is backed by a team that really has the potential to unlock some of the mystery behind recirculating systems for larval culture.”

Though recirculating aquaculture systems have been used for decades, they have only recently been adapted for shellfish hatcheries and are not yet reliable enough for implementation in commercial hatcheries.

“Since we've done so much work here with early-life stages of other marine fish, both vertebrates and invertebrates, we found moving to shellfish was a fairly natural and easy process,” Schwarz said of the move to adapt biofiltration methods for bivalve production.

The center has supported the seafood industry since 1975 by offering technical assistance and conducting applied multidisciplinary research, including recirculating aquaculture systems. A new $10 million research facility, complete with highly adjustable aquaculture research facilities and water quality and microbiology laboratories to support this project, opened earlier this year in Hampton.

“That is not to say we're migrating completely to a closed loop system,” van Senten said. “Instead, we’re hoping to develop a closed-loop option to be employed when necessary. That way, if farmers know that the environmental conditions are deteriorating and need some level of control, they can turn on that system and isolate their production from whatever is happening out in the environment.”

Oysters spend most of their lives stuck in a single spot, opening their shells only to filter food from the water. The early days of an oyster’s life cycle look quite different. In the first weeks of life, newly hatched oyster larvae are without shells and can swim freely.

While an adult oyster can close off, stop feeding, and survive off energy stores when water quality is poor, oyster larvae are exceptionally vulnerable to poor water quality as they must constantly feed to grow and survive. Oyster hatcheries depend on stable ambient water quality to keep oysters healthy in their early weeks.

The need for seed

Hatcheries for young bivalve production play an essential role in the seafood industry by supplying baby oysters, known as oyster seed. They spawn oysters by mimicking conditions in which oysters spawn in the wild. A handful of broodstock oysters can produce millions of fertilized eggs, which hatcheries then nurture from swimming larvae through their metamorphosis into seed and then spat, which are small oysters ready to be sent to oyster farms.

When there is trouble at the hatchery level, there are impacts throughout the whole industry all the way down the supply chain to the consumer.

The impacts of changing environmental conditions are being felt by oyster growers up and down the Atlantic coast, but these challenges are not unique to the region, said van Senten.

"Water quality issues are not manifesting in exactly the same way on every coast because of geographical differences, but every coast of the United States is struggling with water quality and environmental issues impacting coastal aquaculture production," van Senten said.

Aquaculture provides significant economic value to coastal communities and Virginia’s economy. A recent study performed by van Senten and his economics and marketing team revealed that the economic contribution of the Virginia aquaculture industry amounted to more than $177 million for the commonwealth in 2019. Shellfish, including oysters and clams, comprise up to 84 percent of the total economic output from aquaculture.

Virginia is a leading producer of oysters and clams on the Atlantic coast, so for the local economy, for those who work on the water, and for Virginia consumers, the stakes are high for the development of resilience measures in the face of the vexing challenges posed by a changing climate.

A recipe for a living filter

Creating and maintaining stable microbiomes lies at the heart of recirculating systems. It also is vital to the health of shellfish in the early stages of their life cycle.

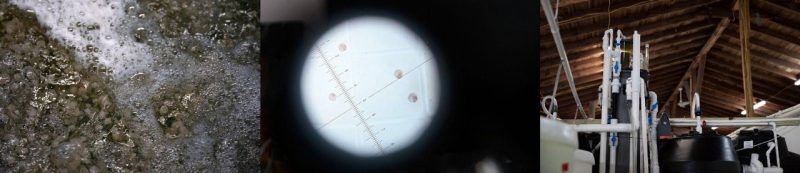

Stable conditions supported by the system help maintain a healthy microbiome or general microbial community as water cycles through a biofilter, a new bioreactor, and a protein skimmer before being reused in the system. The biofilter consists of a team of microbes that remove harmful bacteria like vibrio and chemicals like ammonia that can accumulate in the system.

Reza Ovissipour, assistant professor in the Department of Food Science and Technology, said customizing the recipe of system controls and microbes at work to suit the needs of a hatchery begins with understanding more about the microbial community and the roles different bacteria serve in the system.

Funding from a National Oceanic and Atmospheric Administration Fisheries Saltonstall-Kennedy Grant will allow researchers to continue the analysis to deepen their understanding of the microbiome within the bioreactor. This portion of the project is approaching the midpoint of the two-year grant period.

Ovissipour studies bacterial cultures from samples collected from the recirculating system at Oyster Seed Holdings to measure any changes in bacterial communities throughout. In addition to water samples, the microbial culture medium on which the bacteria thrive is collected.

Plastic beads tumble through the biofilter tanks and serve as the growth media. They provide ample surface area for bacteria to cling to and grow colonies, eventually developing into a gel-like substance known as a biofilm.

"Some bacteria in biofilms control water chemistry, and others control pathogenic bacteria,” Ovissipour said. “We're bringing many different types of helpful bacteria into the mix to work together to maintain an environment suitable for growing oysters."

An alumnua and fourth-generation grower

Growing up, Heather Terry Lusk was not like most kids her age. She was digging clams, grading oysters, and — her favorite — tending to the family's nursery operation.

Her great-grandfather Henry Terry came to the Eastern Shore in the late 1800s to grow ocean salt oysters for Blue Point Oyster company in Long Island, New York. In 1903, he ventured out and established HM Terry Company, and the family’s Sewansecott brand of ocean salt oysters was born.

After graduating from Virginia Tech and later receiving a law degree from Michigan State University, Lusk became an attorney and spent time practicing law on Wall Street. However, her love for oyster and clam farming called her back home to the Eastern Shore, where she put her waders and gloves on, and picked up where she left off.

Being a fourth-generation grower, Lusk knows firsthand, as does her family, the issues that affect oysters.

The company thrived until the 1980s, when Dermo and MSX devastated the oyster population. It would change the industry forever. “Oysters are sensitive to water quality. The Willis Wharf waterfront had four or five oyster houses during this time, and today, they are clam hatcheries because most went out of business. Our company had to pivot.”

Faced with these challenging times, the company worked with the Virginia Institute of Marine Science to develop methods for farming hard shell clams. It has since expanded its operation and facility where it grows small seed purchased from other hatcheries in Virginia like Oyster Seed Holdings. “We were excited to return back to our oyster production roots in addition to our main farming of clams,” said Lusk.

In recent years, Lusk has collaborated with the Virginia Seafood Agricultural Research and Extension Center on projects to enhance the family's operation from clam harvesting to the installation of filtration systems.

“As an alumna of Virginia Tech, it has been rewarding to work with my alma mater in this capacity,” said Lusk.

The realized and potential implications of climate-related pressures for oyster growers, such as HM Terry Company and Oyster Seed Holdings, and oyster lovers alike underscore the need for collaboration between industry and academics.

Schwarz said working with industry to identify and confront emerging challenges facing the seafood industry has been the core driver of the Virginia Seafood Agricultural Research and Extension Center's work since 1975.

He also said it positions this research project to impact the industry in a meaningful way. After all, over two billion oysters are eaten every year.

“We have a second industry partner on board now and we're making very good strides to help remediate the situation,” Schwarz said. “We’re optimistic that continued collaborative efforts will make recirculating systems that are amenable to our hatchery stakeholders and partners.”