Turning trash into treasure

How one Virginia Tech researcher is securing a domestic supply of rare earth elements – which are critical components in emerging green energy technologies – while also reducing the impacts of waste treatment.

Despite their name, rare earth elements are not hard to find. These 17 heavy metals are dispersed in small amounts throughout the Earth’s crust, with some even more abundant than copper. What is rare, however, are the means to recover them economically, efficiently, and safely.

Rare earths are critical components in cell phones, aircraft, and many advanced electronics, and they're becoming particularly important in emerging green energy technologies, such as electric and hybrid vehicles as well as wind energy. However, with little to no domestic production, the United States has historically relied on China for over 80 percent of its rare earths and is vulnerable to disruptions in the supply chain. That vulnerability led to a White House Executive Order last fall declaring a national emergency on their supply, which prioritized the development of domestic sources.

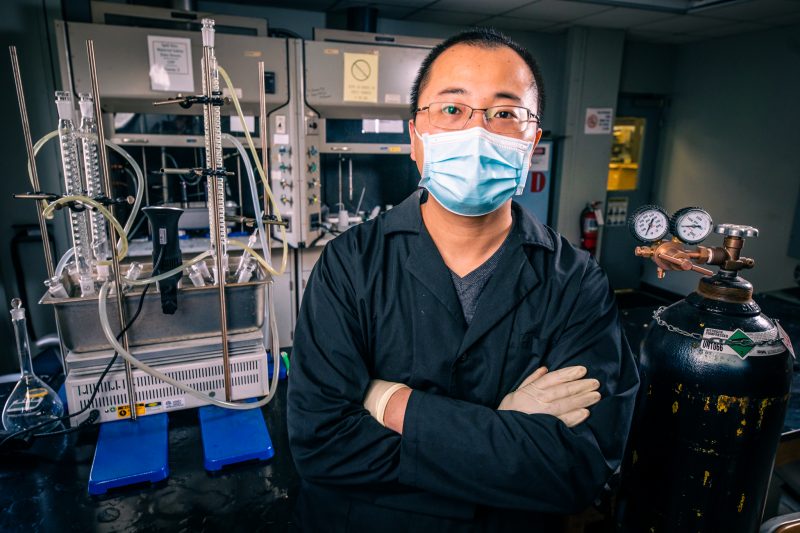

In a trio of projects focused on developing new domestic resource streams for these critical materials, Virginia Tech mining and minerals engineering assistant professor Wencai Zhang is looking at waste byproducts as a potential source of rare earths, which he aims to recover using processes that are more cost effective and environmentally safer than traditional methods.

“Waste handling and rare earth production are two of the biggest issues facing modern society,” said Zhang, “Our projects have great potential to reduce the high costs and environmental impacts associated with waste treatment, while also promoting the establishment of secure domestic rare earth supply chains.”

Rare earths locked in ash

In one project, Zhang is examining the potential of recovering rare earths from residual ash, a byproduct of incinerated municipal solid waste. Each year over 2 million tons of municipal solid waste — ranging from food to plastics and electronic devices — are incinerated in the United States. Incineration reduces a majority of the waste, but leaves behind a small amount of residual ash.

“Normally, the residual ash from municipal solid waste must be treated in disposal facilities because it contains significant amounts of dangerous heavy metals and pollutants,” explained Zhang. “Treating the ash is expensive and accompanied by environmental risks. Currently, one of the only ways to use residual ash is to sequester it in products like concrete or cinder. But if we can find a way to recover the rare earths from the ash first, it would render the ash more environmentally benign, while adding value through the development of a domestic rare earth supply stream.”

With project funding from the Department of Energy’s Advanced Research Projects Agency-Energy, Zhang seeks to understand the conversion mechanisms, or how critical materials change, during incineration. To do this, Zhang and his team have created a synthesized waste, formed by combining electronic waste — such as cell phones and computer components — with samples of incinerated ash.

The combined waste will be incinerated under laboratory conditions, then ground and chemically treated to selectively extract the rare earths cobalt and neodymium. “These elements are the raw materials for batteries and permanent magnets and are critical to many clean energy technologies, such as the turbines used in wind energy,” Zhang said.

Sourcing green energy from red mud

In a second project, Zhang is trying to recover rare earths from bauxite residue, or “red mud,” a waste byproduct of aluminum mining operations.

Extracting aluminum from bauxite generates about one to two and half tons of bauxite residue for each ton of aluminum produced. This residue often ends up in stockpiles at mining sites or in tailings ponds - large, man-made reservoirs that allow the waterborne waste to settle over time.

With 16 million tons of aluminum produced in the U.S. between 2009 and 2019, there are an estimated 16 million tons of bauxite residue locked up in stockpiles and tailings ponds.

“Bauxite residue consists of up to 1 percent rare earths, such as neodymium, lanthanide, and cerium,” said Zhang. “So there are an expected 16,000 tons of rare earths currently sitting in waste stockpiles.”

One of these rare earths, neodymium in particular is essential for the production of the strong magnets needed in a variety of growing green energy technologies. Yet it continues to be in short supply and has been deemed critical in the U.S. due to supply risks.

The aim of this project is to develop new technologies and processes that will recover the rare earths from the bauxite residue with a purity of 95 percent or greater. “By producing high-purity rare earths from the bauxite residue, we can establish a domestic rare earth supply chain, thereby reducing the criticality of these important materials,” said Zhang.

Using food waste to unlock the rare earths in waste

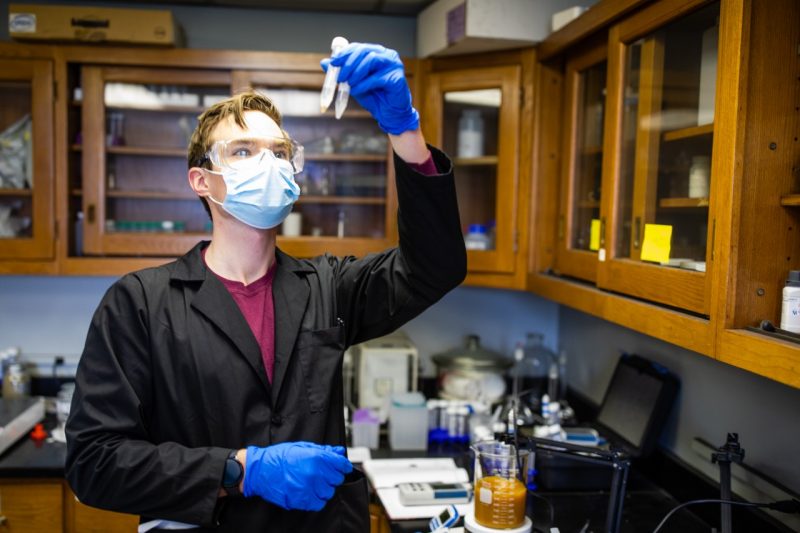

In both of Zhang’s projects, the waste is first processed through physical methods, such as grinding, to make the critical materials easier to recover. Normally, recovery is carried out through a chemical process whereby the rare earths are leached out of the waste through the addition of mineral acids, such as sulphuric acid, which can be toxic and carry known environmental risks.

But in a third project, Zhang and his team are attempting to replace the more harmful mineral acids with safer organic acids that have been derived and microbially converted from food waste.

In this research, funded by a grant from the U.S. Environmental Protection Agency’s People, Prosperity and the Planet (P3) program, the novel organic acids, specifically succinic and lactic acid, will be used to leach out the rare earths from both the incinerated ash and bauxite residue waste.

“Using organic acids has the potential to greatly reduce the high costs and environmental impacts of traditional food waste treatment,” said Zhang, as nearly 40 percent of food in the U.S. — the equivalent of 133 million metric tons — normally ends up in landfills, leading to air and water pollution.

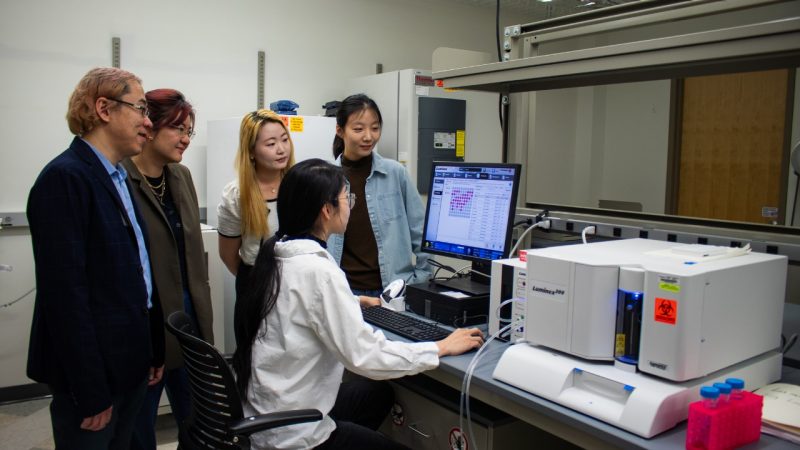

“We are very excited to be working on these important projects that address real problems surrounding our nation’s supply of critical materials,” said Zhang. “The work also allows us to train our undergraduate and graduate students to be the next generation of experts who can continue the development of domestic critical elements.”

The organic acids used in the People, Prosperity, and the Planet (P3) project have been derived from a fermentation process conducted by Haibo Huang, assistant professor of food science and technology in the Virginia Tech College of Agriculture and Life Sciences. The municipal waste and bauxite residue projects are being carried out in collaboration with Phinix LLC, NICHE Industrial Chemicals, and Covanta. Huang, Aaron Noble, and Hassan Amini of West Virginia University serve on the selected projects as co-PIs.