Aerospace engineering labs continue on through faculty’s creative approach

In early March, when the university made the decision to move the remainder of spring semester classes online in response to the global COVID-19 pandemic, faculty and instructors worked diligently to adapt their lecture materials and lesson plans for a semester of remote learning.

For a number of faculty and research associates in the Kevin T. Crofton Department of Aerospace and Ocean Engineering, adapting also meant answering a complicated question: Just how do you make a hands-on laboratory experience possible? They rose to the challenge to turn the remainder of Experimental Methods (AOE 3054) into an engaging, interactive laboratory experience.

With more than 170 students enrolled and 28 lab sections scheduled over the course of two weeks in April, hands-on learning required a team effort. Led by research associate professor Aurelien Borgoltz and William Devenport, director of the Stability Wind Tunnel, the team moved quickly and began carefully planning how to execute an online laboratory experience without sacrificing engagement and student interaction.

The course typically teaches students the basic methods to prepare, perform, and report on experiments that take place at four locations across campus:

- Newport News Shipbuilding AOE Teaching and Research Laboratory, where students can test flow quantities using pressure sensors and particle image velocimetry, static displacement and strain measurements of simple structures, and visualize flow around bodies using smoke flow visualization.

- AOE Electronics Educational Center and Laboratory, where students learn how to use analog and digital instrumentation and apply those concepts to the study of a vibrating beam.

- Aerospace Structures and Materials Laboratory, where students perform mechanical tests (on samples they themselves fabricate) to quantify the tensile, compressive, fracture toughness, and impact energy absorption properties of their material.

- Stability Wind Tunnel, where students perform an aero-acoustic study of a 2D airfoil section.

Every year, the last experiment of AOE 3054 takes place in the Stability Wind Tunnel and is often directly linked to a research project, so each student group performs measurements on a unique configuration and gains the experience of being part of a research team. This year, the experiment consisted of measurements characterizing the noise generated at the trailing edge of a wind turbine blade section. When manufacturers design wind turbine blades, they optimize aerodynamic performance, which leads to power generation and noise signature, as wind turbines located close to populated areas will be slowed or shut down if too loud.

The Stability Wind Tunnel is routinely used by major wind turbine manufacturers, as it is one of the only wind tunnels in the world large enough to reproduce the full-scale conditions experienced by wind turbine blades, while also generating a controlled environment quiet enough to allow for the accurate measurement of sound.

The lab had been scheduled months in advance as the experimental component of an international collaboration between research associate Máté Szőke, of Virginia Tech, the project lead; Lorna Ayton, of the University of Cambridge; and Chaitanya Paruchuri, of the University of Southampton in the United Kingdom. Their purpose is to produce a theoretical model that can predict the noise signature of wind turbine blade sections. Ayton and Paruchuri gave recorded lectures to provide the students with the technical background and motivation behind the experiment.

The students' tasks included measuring airfoil unsteady surface pressure, or the aerodynamic source of the noise; far-field acoustic signature, or the noise itself; and aerodynamic properties of the flow near the trailing edge of the model.

Switching to an online format

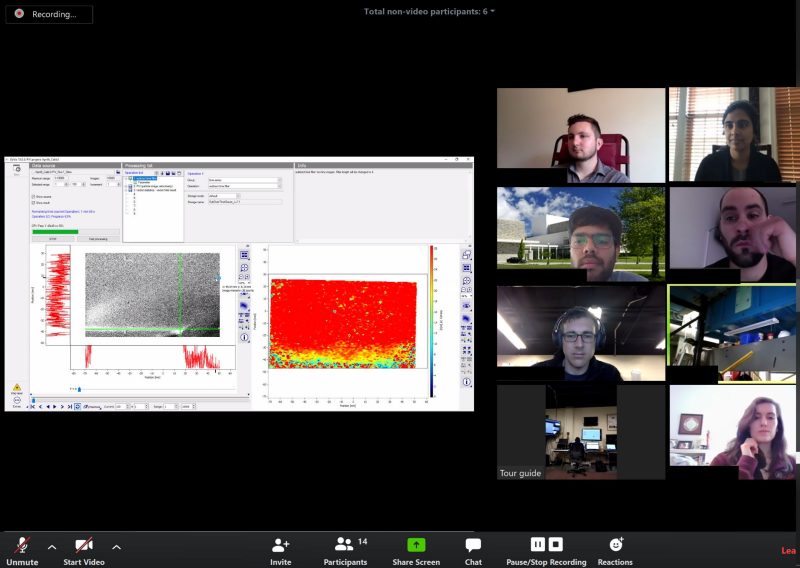

The Stability Wind Tunnel experiment was scheduled for two weeks in April. Instead of simply showing a pre-recorded video, the faculty and research faculty chose to conduct facility tours and experimentation live to generate active student engagement in directing and learning during the lab session. The students, five to eight in each session, were expected to fully participate interactively in the lab, lodging specific requests and asking questions during all phases of the experiment.

“With the change to all-online format, William Devenport and I felt it was important to find a way to make this world-class facility still accessible to the students, but also provide a sense of normalcy to an otherwise extraordinary situation,” said Borgoltz, who also serves as assistant director of the Stability Wind Tunnel.

To execute this type of exercise at a distance and limit the number of individuals on campus, the team set up the instrumentation and communication software so that only the tunnel operator and a research engineer would need to be on-site, in separate rooms. The students, along with an additional technical expert, would participate via Zoom.

During the pre-planning stage, the team developed detailed storyboards, blocking out how the tunnel operator, who doubled as camera operator, would lead the group through the wind tunnel. Equipment was purchased for the tour, including a smartphone, a hand-held gimbal for camera stabilization, and wireless headphones for the onsite experts. Multiple rehearsals were held to determine what was working and where adjustments were needed.

Prior to their scheduled laboratory session, the students were required to watch a pre-recorded video that detailed technical information that could not be easily shown during the live tour. The pre-lab video also taught them how to navigate the Zoom session, including how to switch through the various video feeds, how to pin videos, how to annotate their screen and save screenshots. They were encouraged to participate during the virtual tour through a participation grade.

Just as in a real experiment, each team member was assigned specific tasks to be carried out during the lab, such as maintaining the logbook, preparing data analysis tools to perform data reduction as data is provided to them live, or capture of screenshots to document the facility and instrumentation.

The facility tour, which lasted about 45 minutes, led the students through every aspect of the test: close-up views of the test-section and anechoic chambers and the test article, and the various instruments used to perform the measurements. Students were encouraged to ask the tunnel operator to go back and look more closely at details they may have missed on the video or ask about technical aspects of the tunnel and their upcoming experiment. The tour concluded with introduction to the various measurement systems, including the particle image velocimetry computer, tunnel cameras, surface microphones, and phased array computers.

Back in the control room area, the live testing began with the discussion led by tunnel operator and research engineer. During this period, students were able to observe live visualization of the unsteady surface pressure fluctuations, or the source of the acoustic signature of the airfoil measured by embedded surface microphones; the far-field noise signature, which is measured with a 251-microphone phased array; and aerodynamic measurements of the boundary layer near the trailing edge of the airfoil, which is measured using Particle Image Velocimetry, a system where a pulsed laser is synched with a camera capable of measuring 12,000 images per second to visualize and measure flow velocities.

Students participated in live discussion with the research engineer regarding that data’s collection and analysis. Students also controlled the course of the experiment during a second phase by choosing an obstacle to place on the airfoil surface that influenced the sound, and observed the effects in the subsequent measurements.

Once the experiment ended, the teams of students were provided with their customized data set, as well as pre-measured data sets for the more time-consuming reduction items, such as particle image velocimetry results.

Unexpected results

“A surprising outcome of this initiative is that, in some ways, students are able to get a closer and more detailed view of the experiment than they would do if they were physically present at the facility,” noted Borgoltz. “The Zoom platform allows students to move at will between screens of the four computers running the tunnel and taking the different measurements, as well as camera views of the test section, fan and other areas of the wind tunnel. This is something not possible locally, since some of the computers and camera feeds have to be physically separated in ways that preclude browsing from one to another.”

Borgoltz and Devenport received positive feedback from several undergraduates on their experience. “I believe the experiment in my lab session went very smoothly, primarily due to each and every faculty member being prepared and ready to answer any questions to help clarify the experiment,” said Alan Do, a junior majoring in aerospace engineering, “Compared to previous labs earlier this semester, I would say this session was definitely more interactive. Surprisingly, I found myself proactively listening and asking questions.”

“I think that this was my favorite lab we did this semester,” said Stanley Smeltzer, a junior majoring in aerospace engineering. “If I was having trouble, I didn’t have to wait for the teaching assistant to be available. Since he answered the questions to the entire group, it made the lab very clear. I also think that since a technician was running the tests, we were able to learn the process and get a lot of good data that we could then process and understand more clearly.”

Faculty and research associates involved included Borgoltz, Devenport, assistant research professors Nanyaporn Intaratep and Matthew Kuester, Stability Wind Tunnel engineer Bill Oetjens, and Máté Szőke, who led the experiment setup. Additional support was provided by graduate students Agastya Balantrapu, Danny Fritsch, Aldo Gargiulo, Christopher Hickling, Julie Duetsch, and Vidya Vishwanathan, as well as support from the College of Engineering and the Department of Aerospace and Ocean Engineering.

Written by Jama Green. Photos and Video by Jama Green (unless otherwise noted).