Virginia Tech receives $6 million award to recover crucial rare earth elements

A team of Virginia Tech researchers led by University Distinguished Professor Roe-Hoan Yoon has been selected by the U.S. Department of Energy to build and construct a pilot plant to extract rare earth elements from coal and coal byproducts.

The overall $6 million award for the project is a continuation of an earlier $1 million grant. The pilot plant will be constructed in the central Appalachian coalfields, and participating companies will provide an additional $1.5 million to share the project cost.

Rare earth elements are a set of 17 unique chemical elements found throughout the earth’s crust. They are essential components in modern technologies, ranging from electronics and computer and communication systems to transportation, health care, and national defense.

Producing rare earth elements economically in the U.S. has been a challenge due to competition from low-cost producers abroad. With the recent closure of the only rare-earths-producing mine in the country, the U.S. relies entirely on foreign imports, mainly from China.

Coal and coal byproducts might contain upward of 11 million metric tons of rare earth elements. However, an efficient, safe, and economical means for extraction has not been available — until now.

“Virginia Tech has led the way in researching rare earth element extraction from coal and its byproducts,” said Congressman Morgan Griffith. “Funding for a pilot plant means that the possibilities of applying this technology are more promising than ever before. This project has shown great potential for the future of the coalfields and for our economy.”

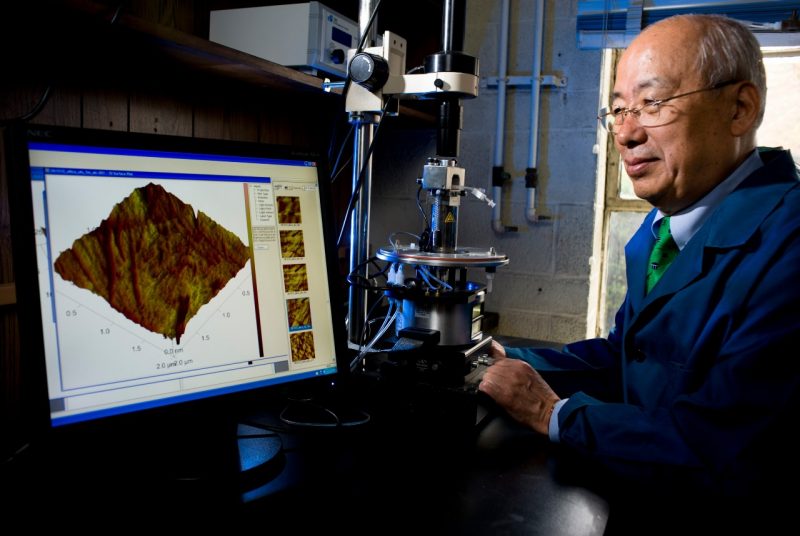

The challenge with extracting rare earth elements from coal byproduct is that the concentrations of the elements are low, and the grain size of the elements is small, typically less than 5 microns.

“Rare earth elements are actually not as rare as they say,” explained Yoon, who is also the Nicolas T. Camicia Professor in Virginia Tech’s Department of Mining and Minerals Engineering. “What makes them rare is the difficulty in separation.”

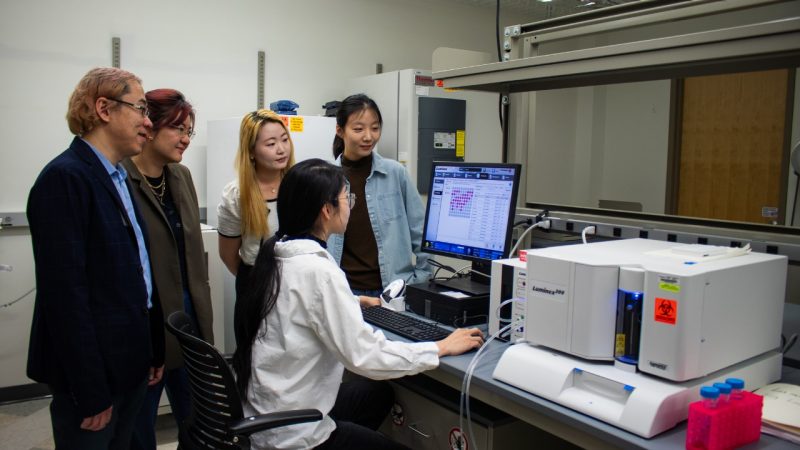

Yoon and his group developed novel separation and extraction methods to meet the challenges, including the patented hydrophobic-hydrophilic separation process that can recover ultrafine particles. An advantage of extracting rare earth elements from coal byproducts is that the cost of mining has already been paid for during the course of producing coal.

In the DOE-funded project, the new separation processes will be tested at a pilot scale to collect scale-up and cost information. The success of this project will be a stepping stone for producing salable rare earth oxides commercially in the coalfields of Central Appalachia.

The co-principal investigators for the project include Gerald Luttrell, the E. Morgan Massey Professor of Mining and Minerals, and Aaron Noble, associate professor of mining and minerals engineering. The project will be carried out in cooperation with the University of Kentucky and the Minerals Refining Company of Richmond, Virginia.

— Written by Angelo Biviano