Biofuel processes to be developed by French biotechnology company, Biomethodes

Biométhodes, a French biotechnology company in Evry, has signed an exclusive and worldwide option-to-license agreement with Virginia Tech Intellectual Properties Inc. (VTIP) for multiple technologies for converting biomass to bioethanol and biohydrogen.

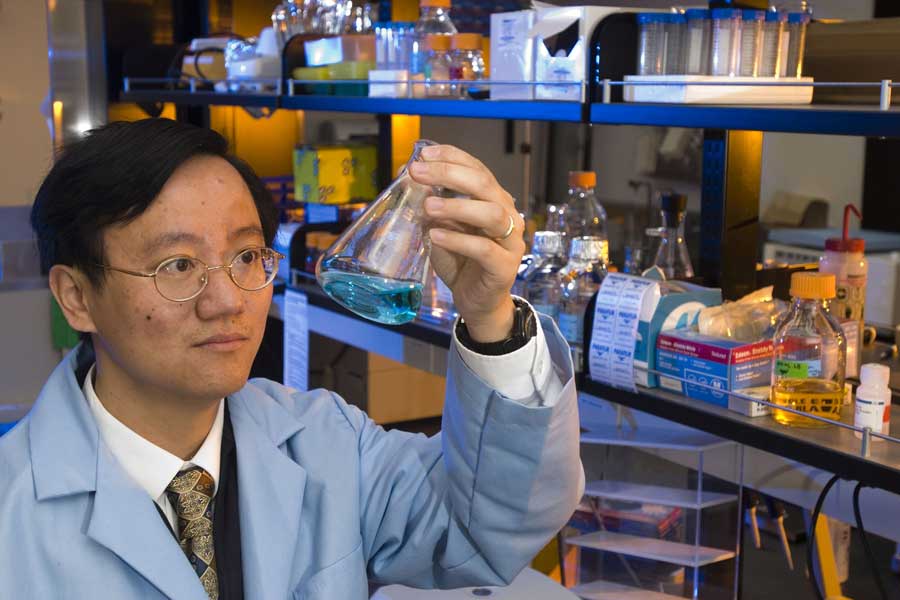

The processes were invented by Percival Zhang, assistant professor of biological systems engineering in the College of Agriculture and Life Sciences at Virginia Tech. An integrated biorefinery pilot plant in Virginia is envisioned to advance the process for the conversion of biomass into ethanol and valuable co-products, focusing especially on biomass pretreatment. The process for transformation of biomass into hydrogen will be developed in France and will be validated through a biohydrogen fuel cell prototype and small-scale model car.

Zhang developed a novel and innovative process for releasing sugars that can be fermented into ethanol from non-food sources into sugars that can be converted to ethanol. His process uses enzymes and mild and recyclable physicochemical conditions that do not require high pressure or high temperature. The gentle pretreatment process also results in no sugar degradation and separates other highly profitable products, such as lignin and acetic acid. “More revenues from lignocellulose components other than sugars would be vital to the success of biomass refineries,” said Zhang.

According to Gilles Amsallem, Biométhodes chief executive officer, “The pilot plant will integrate two major technologies – Virginia Tech’s pretreatment process, which breaks down the biomass, and Biométhodes’ hydrolysis enzyme optimization technology to improve the cellulose degradation into fermentable sugars.”

Goals are to increase hydrolysis efficiency, optimize production of enzymes, reduce enzyme cost, and then do industrial scale testing with a commercial process deployment. “Our strategy is to enable next generation of biocatalysts and biofuels by co-developing pre-industrial processes, to be further integrated by industrial partners,” Amsallem said.

John Talerico, Virginia Tech Intellectual Properties licensing associate, said, “We have a process with the potential to economically produce ethanol from biomass on the scale of billions of gallons per year scale.”

Locating the plant in Virginia will enhance the collaboration with Zhang as the process is optimized, Amsallem said. A United States-based plant is also important because, “In the United States, the time to market is shorter for ethanol,” said Amsallem. “The [United States] and Brazil already have first generation technologies based on ethanol as a fuel.”

However, the European Union is very active in funding and developing hydrogen as a fuel, Amsallem said. “All the conditions for the success of the hydrogen project exist in Europe and Biométhodes technologies are the most appropriate to develop this process.”

Using synthetic biology approaches, Zhang and colleagues from Oak Ridge National Lab and the University of Georgia proved that a combination of 13 enzymes never found together in nature will completely convert polysaccharides into hydrogen when and where that form of energy is needed.

Polysaccharides like starch and cellulose are used by plants for energy storage and building blocks. They are very stable until exposure to enzymes, which degrade them into carbon dioxide and hydrogen through a very efficient artificial metabolic chain.

The vision is for the hydrogen to be used by fuel cells to create electricity. Water byproduct would then be recycled to the starch reactor, to create a very clean process. Laboratory tests also confirm that it all takes place at low temperature -- about 86 degrees Farenheit -- and normal atmospheric pressure.

Biométhodes will scale up the proven laboratory-scale process to deliver fuel cells, a model car as an initial prototype, a battery prototype, and, in the end, a car prototype. According to the company’s plan, the goal is to enter into co-development agreements with hydrogen fuel cell companies. These agreements will aim to develop the Biométhodes hydrogen-on demand technology implemented into prototypes that can be tested with, and ultimately incorporated into, the design of commercial fuel cells for portable and other mobile applications.

“Our technologies and Biométhodes’ expertise in enzyme optimization should create best conditions for success of commercial development of biohydrogen and second generation biofuels in Europe and the [United States],” said Talerico.